Stoner Molding Solutions Launches RotoFlow™ Mold Release for Polyolefin and Nylon Resins

Quarryville, PA, USA — Stoner Molding Solutions, the world’s largest manufacturer of rotational mold releases, announces the development of RotoFlow™ a high-efficiency mold coating for rotomolded polyolefin and nylon resins.

Stoner RotoFlow™ is proving the “small stuff” often matters most in rotational molding – especially for cause of defects, scrapped parts, and decreased production efficiency.

Stoner RotoFlow™ is proving the “small stuff” often matters most in rotational molding – especially for cause of defects, scrapped parts, and decreased production efficiency.

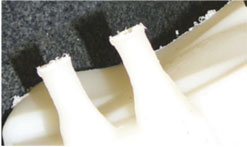

Inserts, tight radii, threads, and deep cavities are often hard-to-fill areas of rotationally molded parts. This common problem can result in weak or defective components of the molded part often leaving it unusable. Stoner RotoFlow™ increases the flow of polyolefin and nylon resins into these difficult areas producing a fully molded part and nearly eliminating voids, pinholes, bridging, thinning, and static lines on the surface.

Stoner RotoFlow™ users have reported higher part quality, increased production efficiency, and reduced operational waste allowing them to achieve higher production goals in less time using this product.

Stoner RotoFlow™ does not contain ozone depleting substances or chlorinated solvents. Stoner RotoFlow™ is sprayed directly onto the internal mold surface and is suitable for use with most metal surfaces. Stoner RotoFlow™ is available at www.stonersolutions.com/trasys.

Stoner RotoFlow™ does not contain ozone depleting substances or chlorinated solvents. Stoner RotoFlow™ is sprayed directly onto the internal mold surface and is suitable for use with most metal surfaces. Stoner RotoFlow™ is available at www.stonersolutions.com/trasys.

Benefits of Stoner RotoFlow™

- Improves the quality and consistency of rotomolded polyolefin and nylon parts.

- Removes pinholes, voids, and blow outs.

- Improves the appearance and operational performance of threads.

- Increases the strength of inserts.

- Contains no Class I or Class II ozone depleting substances.

- Contains no CFC or HCFC propellants or solvents.

- Contains no chlorinated solvents such as 1,1,1 trichloroethane or methylene chloride.

from an article at RotoWorld®

https://rotoworldmag.com/new-stoner-rotoflow-saves-time-and-%e2%80%a8money-for-rotational-molding-industry/

No comments:

Post a Comment